Key Takeaways

- Proper selection of pipe fittings and materials dramatically increases system reliability.

- Innovative technologies, like smart pipe fittings, can boost system efficiency and monitoring.

- Regular maintenance and skilled installation are crucial to extending system lifespan.

Introduction

Industrial systems depend on a web of pipelines and components that must perform reliably under varying pressures, temperatures, and environments. Pipe fittings are vital among these components—they connect, redirect, and extend pipelines to ensure consistent flow and system performance. Choosing a trusted supplier such as Cruco Mill & Industrial Supply is essential for acquiring high-quality fittings built to withstand industrial demands and help prevent costly system failures.

Inspection, compatibility, and technological advancements have become central to pipe fitting selection. Industry experts emphasize the mechanical aspects and the importance of proper material selection and advanced installation methods to limit maintenance needs and system downtime. With guidance from reliable sources and partnerships—like working with Cruco Mill & Industrial Supply—teams can optimize every facet of their piping infrastructure for safety and efficiency.

Types of Pipe Fittings

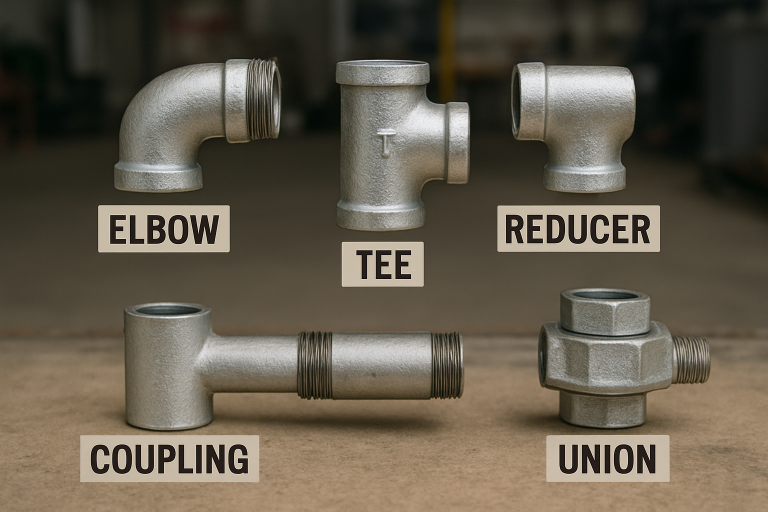

An array of pipe fittings accommodates the complex layouts of industrial piping systems. Each type is designed to solve specific connection and flow challenges.

- Elbows: These fittings change the direction of the pipe run, enabling pipelines to navigate around obstacles or fit within a limited space. Common varieties include 45-degree and 90-degree elbows.

- Tees: Tee fittings split or combine the flow of fluids, allowing pipelines to branch out to different areas of an industrial facility.

- Reducers: Used when piping of different diameters must be connected, reducers can manage the transition smoothly, minimizing turbulence and pressure loss.

- Couplings: Simple but essential, couplings join two straight pipe sections together for permanent or temporary assemblies.

- Unions: Unlike couplings, unions are designed for easy removal, making them invaluable for sections that require maintenance or regular inspection.

The choice of fittings must be informed by system design, operating pressure, media (fluid or gas), and required maintenance accessibility.

Material Considerations

The operating environment directly influences the ideal pipe fitting material. Proper assessment ensures that fittings resist corrosion, withstand operational stresses, and maintain compatibility with conveyed media. Common options include:

- Steel: Known for its immense strength and ability to withstand high pressures and temperatures. Steel is often used in oil, gas, and heavy industrial settings.

- Brass: Valued for its corrosion resistance and machinability, brass is especially suitable for water systems, HVAC, and chemical applications.

- Plastic: Lightweight and resistant to a wide range of chemicals, plastic fittings are ideal for process applications involving corrosive media and sometimes potable water systems.

Understanding the environment—including temperature ranges, pressure cycles, and chemical exposure—is critical to making the right choice. Selecting the wrong material can lead to premature failures, hazardous leaks, and expensive repairs. For a more comprehensive material guide, review this resource from Engineering Toolbox.

Installation Best Practices

Effective installations start with meticulous planning and attention to detail. Even the highest quality pipe fittings will underperform if installed carelessly or without strict adherence to guidelines. Installation best practices include:

- Ensure that every pipe end is free of burrs, dirt, and damage. Clean, properly cut pipe ends ensure a tight and proper fit, reducing leak risk.

- Use the right sealing technique for the fitting. Threaded fittings may require PTFE tape or pipe dope, while flanged fittings use compatible gaskets to prevent leaks.

- Observe manufacturer torque and alignment specifications. Overtightening can crack fittings, while loose joints are prone to leaks and failures.

Adhering to proven installation standards also protects operators and facility integrity, making routine maintenance and inspections easier and safer.

Maintenance and Inspection

No matter how precisely fittings are selected and installed, regular maintenance is fundamental to maximizing lifespan and preventing emergencies. Maintenance routines should include:

- Scheduled inspections are essential in high-risk zones where corrosion or vibration is likely.

- Immediately replace worn, corroded, or damaged fittings to avoid catastrophic failures.

- Detailed record-keeping of repairs, replacements, and inspections. A maintenance log helps predict future needs and supports compliance with industry standards.

As outlined by organizations like the Manufacturing Enterprise Solutions Association (MESA), proactive maintenance reduces the risk of unscheduled downtimes, protects worker safety, and helps control operational costs.

Innovations in Pipe Fitting Technology

The industrial world is quickly embracing new technologies. As described in a detailed research study, innovative pipe systems integrate digital sensors into pipe fittings, providing real-time monitoring of pressure, flow, and potential leaks. These systems enable predictive maintenance by alerting operators before escalating issues, improving long-term safety and energy efficiency.

Benefits of Smart Pipe Systems

- Early leak detection to prevent environmental contamination and equipment damage

- Continuous data analytics for process optimization

- Reduced labor costs due to more targeted maintenance

As automation and remote monitoring become standard, organizations investing in these innovations will likely see improvements in performance, sustainability, and risk management.

Final Thoughts

Selecting the right pipe fittings, from steel elbows in high-pressure lines to plastic couplings in corrosive environments, is the foundation of any reliable industrial system. Establishing supplier relationships with leading companies like Cruco Mill & Industrial Supply, prioritizing best installation practices, and investing in regular maintenance allow industrial teams to maximize efficiency and safeguard operations. In a changing industrial landscape, staying informed about the latest technologies and industry developments ensures systems remain robust, compliant, and future-ready.