Fluidairedynamics.com serves as the digital hub for Fluid-Aire Dynamics, a compressed air systems specialist operating across major manufacturing centers in the Midwest and beyond. Founded in 1983 in a modest Franklin Park, Illinois garage, the company has grown into a multi-location operation serving Chicago, Milwaukee, Minneapolis/St. Paul, Detroit, and Philadelphia. This expansion reflects sustained growth over four decades in the industrial equipment sector, building expertise specifically around rotary screw air compressor systems and the infrastructure that supports them.

The service portfolio addresses the complete lifecycle of compressed air systems. System design represents one end of the spectrum—Fluid-Aire works with facilities to plan new installations or reconfigure existing setups, studying unique applications to ensure efficient air production from the compressor room through to the distribution points. Installation services handle the physical setup, accounting for heat ventilation, power source proximity, voltage requirements, maintenance clearances, and future expandability. The company mentions having completed hundreds of installations, providing a knowledge base for addressing different facility configurations and operational needs.

Equipment rental fills a practical gap when systems go down or need temporary augmentation. Fluid-Aire maintains what it describes as a large fleet of air compressors and dryers available for rent, with installation teams handling delivery, placement, wiring, and piping to minimize downtime. When the rental period ends, the team removes the equipment and can install permanent replacements—either new or rebuilt units. This rental infrastructure provides a safety net for operations that can't afford extended outages while waiting for permanent solutions.

Preventive maintenance programs aim to avoid costly emergency repairs. The company frames regular PM as essential for safe and energy-efficient operation, positioning routine maintenance costs as negligible compared to emergency repair expenses and production shutdowns. Factory-trained technicians handle these scheduled services, checking systems to catch issues before they escalate into failures. The emphasis on prevention suggests a proactive approach to equipment reliability rather than purely reactive service calls.

When breakdowns occur, the repair service operates around the clock including weekends and holidays. The company backs this 24/7 availability with a four-hour emergency response guarantee—if a certified technician doesn't arrive on-site within four hours, the $250 elite service fee gets waived. This time commitment addresses the urgency that industrial facilities face when compressed air systems fail, since many manufacturing processes depend on continuous air supply for operation.

The company specializes in rotary screw compressors rather than trying to cover every compressor type. This focused expertise means technicians know these specific systems thoroughly—from installation mechanics through maintenance requirements to repair procedures. Fluid-Aire services its core brand PneuTech while also maintaining equipment from other major manufacturers including Atlas Copco, Ingersoll Rand, Quincy, and FS Elliott. This multi-brand capability lets facilities consolidate service needs with one provider even if they run different equipment brands across their operations.

Industry coverage spans diverse sectors with varying compressed air requirements. Oil and gas operations, chemical and petrochemical plants, electronics and engineering firms, agriculture and farming operations, general manufacturing facilities, mining operations, pharmaceutical manufacturing, food and beverage production, building fire safety systems, aerospace and military applications, automotive manufacturing, and woodworking businesses all fall within the company's service scope. Each industry brings distinct demands—pharmaceutical and food processing need especially clean air, while mining requires systems that function in harsh environments.

Geographic reach centers on a 90-mile radius from each service facility. The Schaumburg office at 550 Albion Avenue serves the Chicago metropolitan area. Franklin, Wisconsin handles Milwaukee-area clients. Burnsville, Minnesota covers Minneapolis/St. Paul territory. Detroit and Philadelphia have their own service locations. This multi-city footprint allows the company to serve major manufacturing corridors across the Midwest and Mid-Atlantic regions with relatively quick response times compared to distant providers.

Customer testimonials reflect satisfaction with both products and service. One client from Krampade mentions excellent product lines at good price points combined with a knowledgeable sales team, noting plans to return for future capacity upgrades. Another customer from Pullman Sugar describes a salesman who answered every question thoroughly, with prompt delivery and setup that met their needs. The service technician received praise for product knowledge, post-service cleanup, and sharing tips on prolonging unit life. These accounts suggest attention to the full customer experience from initial consultation through installation and ongoing support.

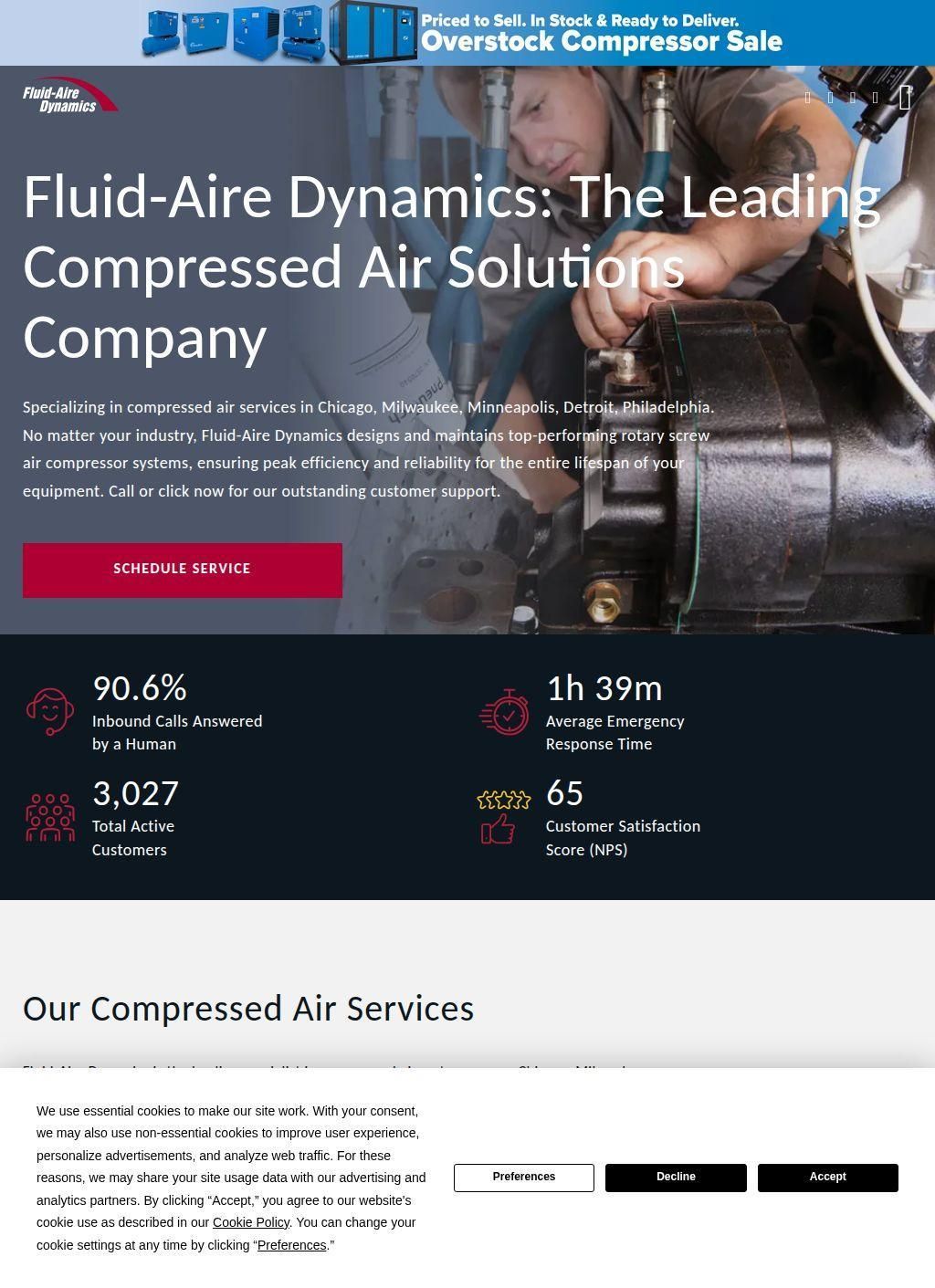

The company reports impressive operational metrics. All inbound calls get answered by humans rather than automated systems. Average emergency response time stays well within the four-hour guarantee window. The business serves thousands of active customers across its territory. Customer satisfaction scores using Net Promoter Score methodology indicate strong approval ratings, though specific numbers aren't detailed publicly. These metrics point to operational systems designed around responsiveness and customer retention.

Extended warranty options complement standard coverage on air compressor sales and services. This additional protection gives buyers peace of mind on their system investments, extending the safety net beyond manufacturer warranties. The availability of extended coverage suggests confidence in the equipment being sold and the quality of installation work being performed—companies don't typically offer extended warranties if they expect high failure rates or service problems.

Contact happens through multiple channels. The main phone line 800-371-8380 provides toll-free access across the service territory. A direct line at 847-678-8388 reaches the Schaumburg headquarters. Email inquiries go to info@fluidairedynamics.com. The website includes contact forms for service requests, quotes, and general information. This multi-channel approach accommodates different communication preferences, whether customers prefer phone conversations for immediate answers or written correspondence for documented exchanges.

The company maintains an active presence beyond just industrial sales. An eBay store sells compressed air equipment and parts, extending market reach to buyers who prefer that purchasing platform. LinkedIn profiles keep business contacts updated on company developments. The combination of traditional industrial distribution channels with modern e-commerce platforms reflects adaptation to how different customer segments prefer to research and purchase equipment.

Fluid-Aire emphasizes its understanding of how downtime affects customers. The website messaging repeatedly returns to minimizing production interruptions—whether through preventive maintenance that catches issues early, rapid emergency response when failures occur, or rental equipment that bridges gaps during repairs or upgrades. This customer-centric framing positions the company not just as equipment suppliers but as partners in maintaining operational continuity for manufacturing and industrial operations that depend on reliable compressed air systems.

Business address

Fluid-Aire Dynamics

225 Spring Lake Drive,

Itasca,

IL

60143

United States

Contact details

Phone: 847-678-8388